Project

polaris, the N8 high performance computer, is being used to investigate the microstructures within fusion reactor components that impact thermal performance.

engineers often use computer models to predict how their design will perform under certain scenarios. however, these models tend to be idealised, therefore omitting micro scale features such as defects that may arise during the manufacturing process.

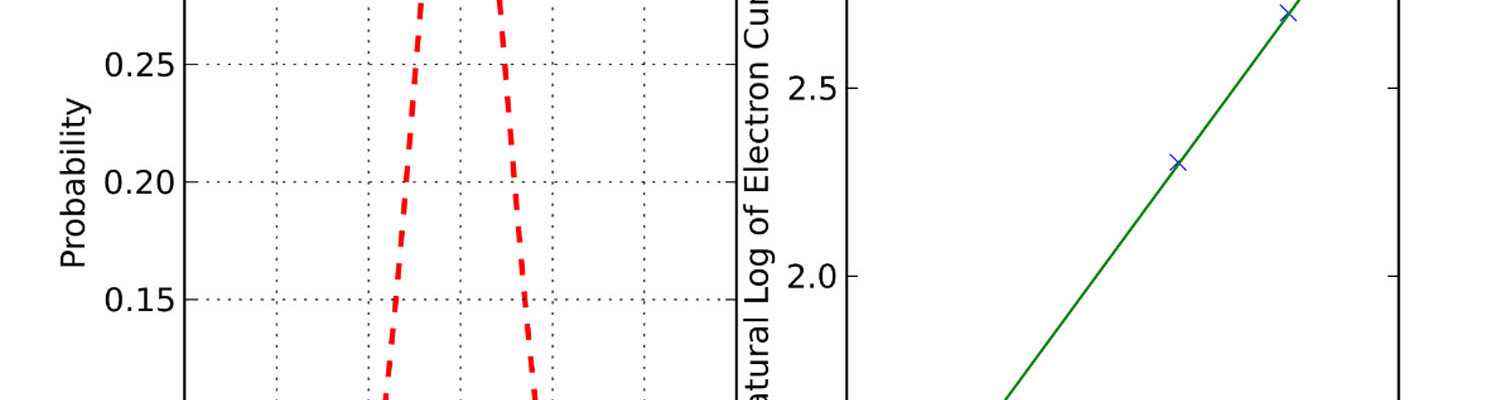

an emerging technique shown to have improved accuracy converts 3-d images of real manufactured components into computer models. these images can be collected by various methods, such as ct or mri scanners similar to those found in hospitals. these image-based models can then predict the behaviour of actual, rather than idealised, components.

Partners

- University of Manchester

- Culham Centre for Fusion Energy

- Department of Applied Science and Technology, Politecnico di Torino

Delivery

a difficulty with using computer models using 3-d images of actual components is that the models produced have very high resolutions requiring extremely large amounts of computing power. additionally, currently available commercial software is not well equipped to perform simulations of this magnitude. therefore the open source code parafem was used on the n8 high performance computer, which enabled successful running of such large models by dividing the calculations into manageable chunks to be solved using thousands of computer processors simultaneously.

Impact

by harnessing the same process as that which powers the sun, fusion power promises to deliver an effectively limitless supply of energy without producing carbon emissions or long term nuclear waste. to achieve this, two specific forms of hydrogen gas are heated to a temperature that is ten times hotter than the sun’s core and held in place by superconducting magnets. the edge of this gas still reaches temperatures of up to 3000 °c and the challenge for engineers and materials scientists is to develop a vessel capable of containing this process. improved predictions of material behaviour, thus component performance, through high accuracy computer models are of utmost importance in achieving this.

although developed for use with components for fusion, this technique has a broad application to most engineering fields. as well as being used for research and development, it is envisaged that a streamlined or automated deployment of the technique could be included in a manufacturing line to assist with quality assurance control.

Success

this work studied a sub component of the iter divertor, the region of the fusion reactor where heating is at its greatest. three dimensional images were collected by x-ray imaging and in applying this technique, small voids not anticipated were found.

More Details

N8 HPC ran from 2013-2018, offering a shared ‘Tier 2’ HPC facility underpinning world-class research, enabling collaborations between the member institutions of the N8 Research Partnership and creating the opportunity to engage more effectively with business and the community.

N8 HPC has now become the N8 Centre of Excellence in Computationally Intensive Research (N8 CIR)

analysis using the n8 hpc showed that if gone unnoticed these could have caused the component to fail. however, this technique allowed recommendations to be made to reduce this risk. due to the success of this work, culham centre for fusion energy will continue to pursue this avenue of research utilising high-resolution modelling of novel materials.

Testimonial

“using commercial software on a high-spec workstation would have taken eight months to achieve what was solved with parafem on the n8 high performance computing facility in one day. this allowed us to perform analysis to a level of detail which would have previously been impractical.”

Dr Evans